PNP set: Electrical explosion of a wire in a gaseous environment

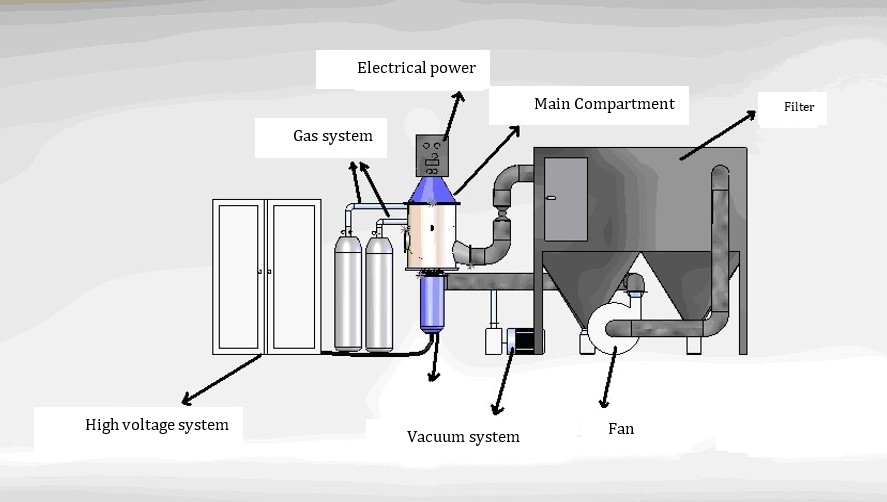

This device produces nanometer-sized powder through the method of electrical wire explosion on a semi-industrial and industrial scale. In this method, by applying very high voltage and current, the wire undergoes an electrical explosion, transforming into metallic or metal oxide nanoparticles. In essence, this technology allows any thin wire, regardless of its material, to be converted into nanoparticles. The operating principle of this device, along with its schematic diagram, is shown in the figure below. The voltage applied to this device is in the range of 10 to 50 kilovolts. In general, the mechanism of nanoparticle production in this method is as follows: an electrical current, along with a very high voltage, enters the thin wire, causing it to electrically explode and transform into metal vapor, plasma, and ultimately, nanoparticles. If the gaseous environment of this explosion is inert, metallic nanoparticles are produced; if the gaseous environment is oxidative, metal oxide nanoparticles are formed.

The specifications of some products:

Application | Shape, Size | Product | Gaseous media | Wire used |

Solid fuel | Spherical, 50 nm | Al-pure | Ar | Al |

Solid fuel | Spherical, 50 nm | Al- passivated | Ar | |

Fuel, resins, coatings and nanocomposites | Spherical, 40 nm | Al2O3 | O2+Ar | |

Coatings and powder metallurgy | Spherical, 70 nm | Cu | Ar | Cu |

coatings | Spherical, 70 nm | CuO | O2+Ar | |

Medical-Pharmaceutical, Water Purification | Spherical, 90 nm | Fe | Ar | Fe |

Medical-Pharmaceutical | Spherical, 90 nm | Fe2O3 + Fe3O4 | O2+Ar | |

Hygiene-cosmetics | Spherical, 80 nm | ZnO | O2 | Zn |

Given that this device is capable of producing various types of metal Nano powders and metal oxides from which wires can be made can imagine the variety of applications of the products by this device. Among the products are such things as additives to reduce vehicle fuel, pigments of various colors, cooling fluids, magnetic fluids, health-cosmetic products, powder metallurgy for making various parts, making catalysts, and so on.

The features and benefits of PNP include:

-Ability to produce various types of metal Nano powders from wire in one step

-Production of spherical Nano powders with a size of less than 100 nanometers

-High efficiency of Nano powder production

-Possibility of producing metal oxide and metal nitride Nano powders

-Ability to produce Nano powders on a large scale

Device specification: | |||

Model | PNP10K-A | PNP50K-C | |

output voltage | 8-10 KV | 20-50 KV | |

input power | 1P 220VAC 3 KW | 3P 380VAC 10 KW | |

explosion sequence | 1-5 sec | 1-5 sec | |

wire | 0.2 mm | 0.3 mm | |

30-80 mm | 100-200 mm | ||

All conductive metals | All conductive metals | ||

particle size | 10-100 nanometer | 10-100 nanometer | |

production capacity | 40 gr/hr | 300 gr/hr | |

control system | touch screen | touch screen | |

device weight | 200 kg | 800 kg | |